Our small custom injection molding machine handles parts up to 2 oz - ideal for the small components, enclosures, covers, and other molded parts typical in product development. The machine is set up for quick changeovers, allowing us to run different parts and materials efficiently during the prototyping phase.

For the fastest possible turnaround, we 3D print molds using materials designed to withstand the injection molding process. These molds are ideal for initial testing and design validation when speed matters most - allowing us to produce molded parts in days rather than weeks. Best suited for lower-volume runs and less demanding materials.

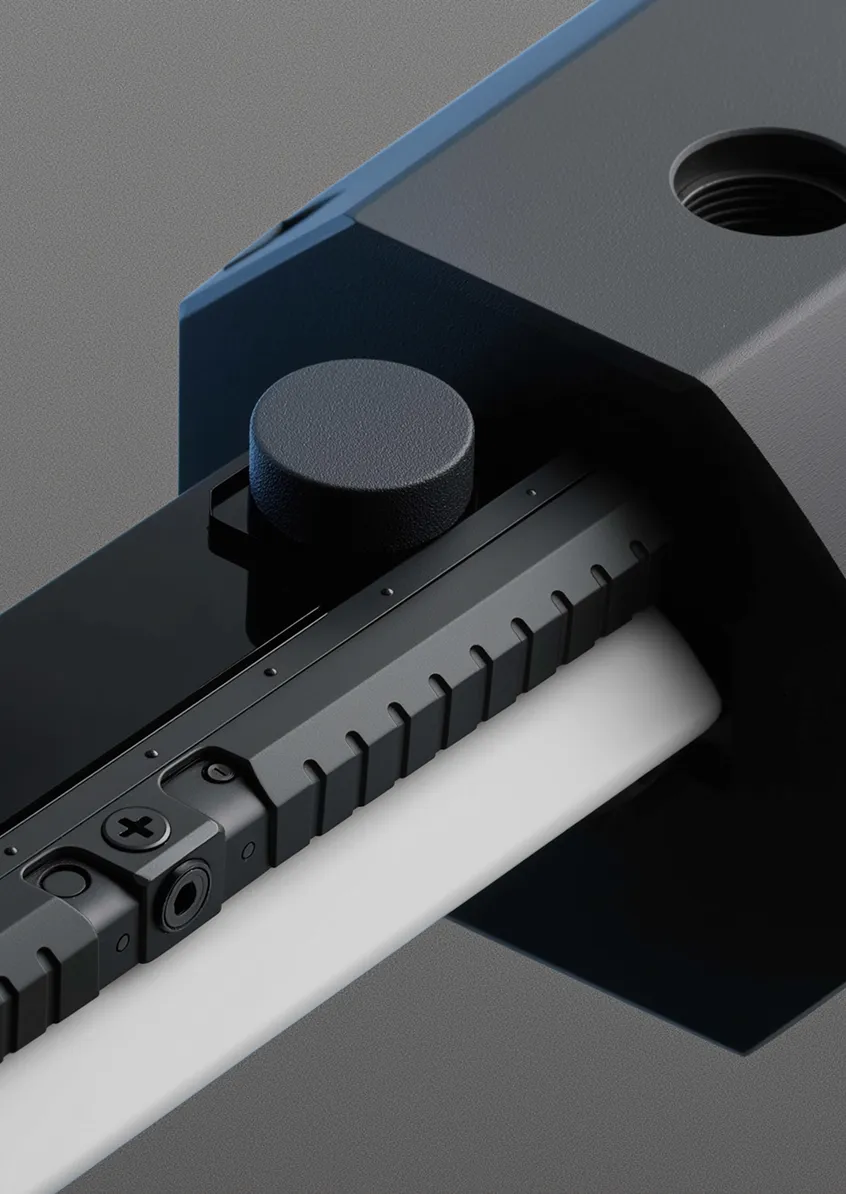

When greater accuracy, tighter tolerances, or more demanding materials are required, we machine molds from aluminum on our 5-axis CNC. These molds offer better surface finish, longer life, and the precision needed for parts with tight dimensional requirements. They're the right choice for higher-volume prototype runs or when the molded parts need to closely represent production quality.