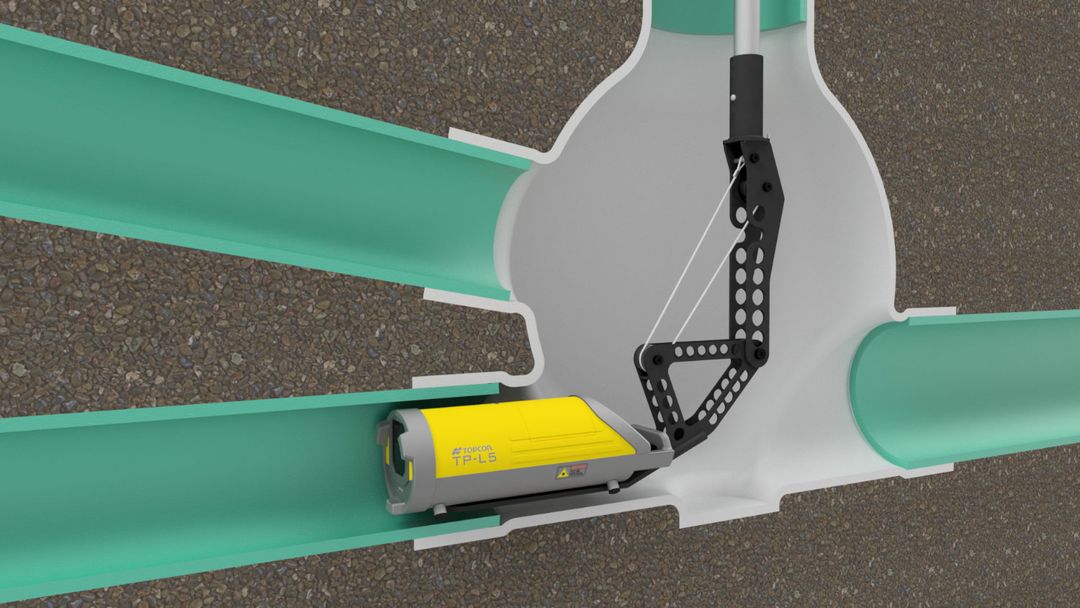

We bring together parts fabricated in-house - machined, 3D printed, laser cut, injection molded, and soldered - with purchased components such as fasteners, bearings, seals, motors, and electronics, as well as any client-supplied existing parts.

We build the complete product from individual components, following the intended assembly sequence. This step tests fit, clearances, fastener access, and assembly order - identifying any issues that only become apparent when you're physically putting the product together.

The assembled prototype is put through its paces - testing performance, durability, ergonomics, and function against the product's specifications and intended use conditions. Testing is tailored to what matters most for your product.

Every assembly reveals insights. We document opportunities to reduce part count, simplify assembly steps, adjust tolerances, and make the product easier and cheaper to build at scale. These findings are incorporated into the next design revision.

Test results and assembly observations are documented and reported back to you and our engineering team. The report covers what worked, what didn't, and what we recommend changing. Findings drive the next design iteration - and the cycle repeats until the product is ready for production.