We help you find manufacturers suited to your product, volume, and budget. This includes identifying candidates, requesting and evaluating quotes, assessing technical capabilities and quality systems, and recommending the best fit.

We obtain and compare quotes from multiple vendors, ensuring that specifications are clearly communicated and that pricing is comparable across suppliers. This gives you the information you need to make confident sourcing decisions.

We help define inspection criteria, acceptance standards, and quality control processes for your production line. This includes creating the QC checklists, inspection procedures, and test guides your team or manufacturer needs to maintain consistent quality.

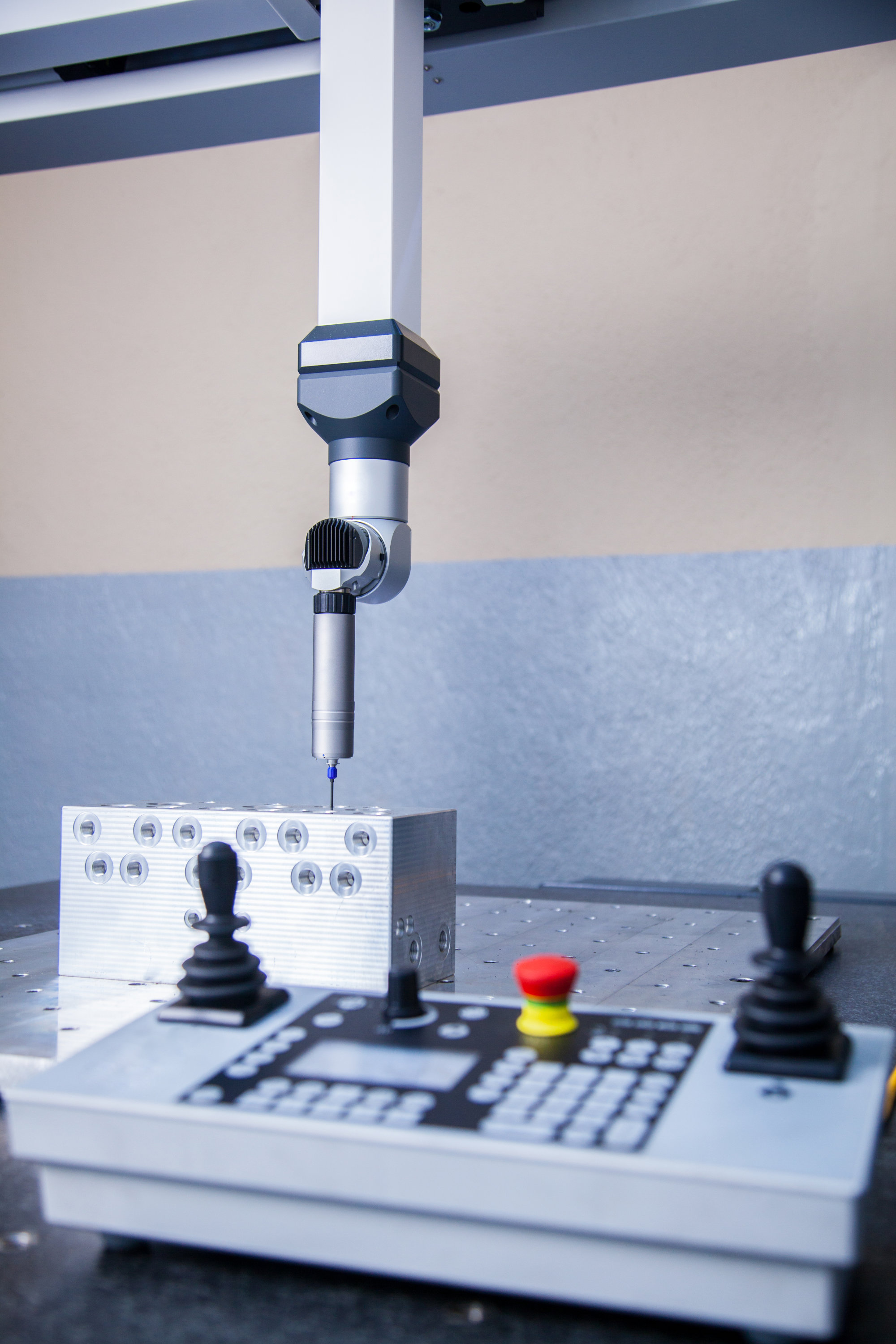

For products where external manufacturing isn't the right fit - whether due to low volume, high complexity, or tight timelines - we can manufacture directly in our shop. Our CNC machining, laser cutting, 3D printing, injection molding, and assembly capabilities cover a wide range of product types.

After launch, we remain your engineering partner. This includes managing design revisions as the product evolves, troubleshooting production issues when they arise, improving the product based on field feedback, and creating updated documentation as the product and production process mature.