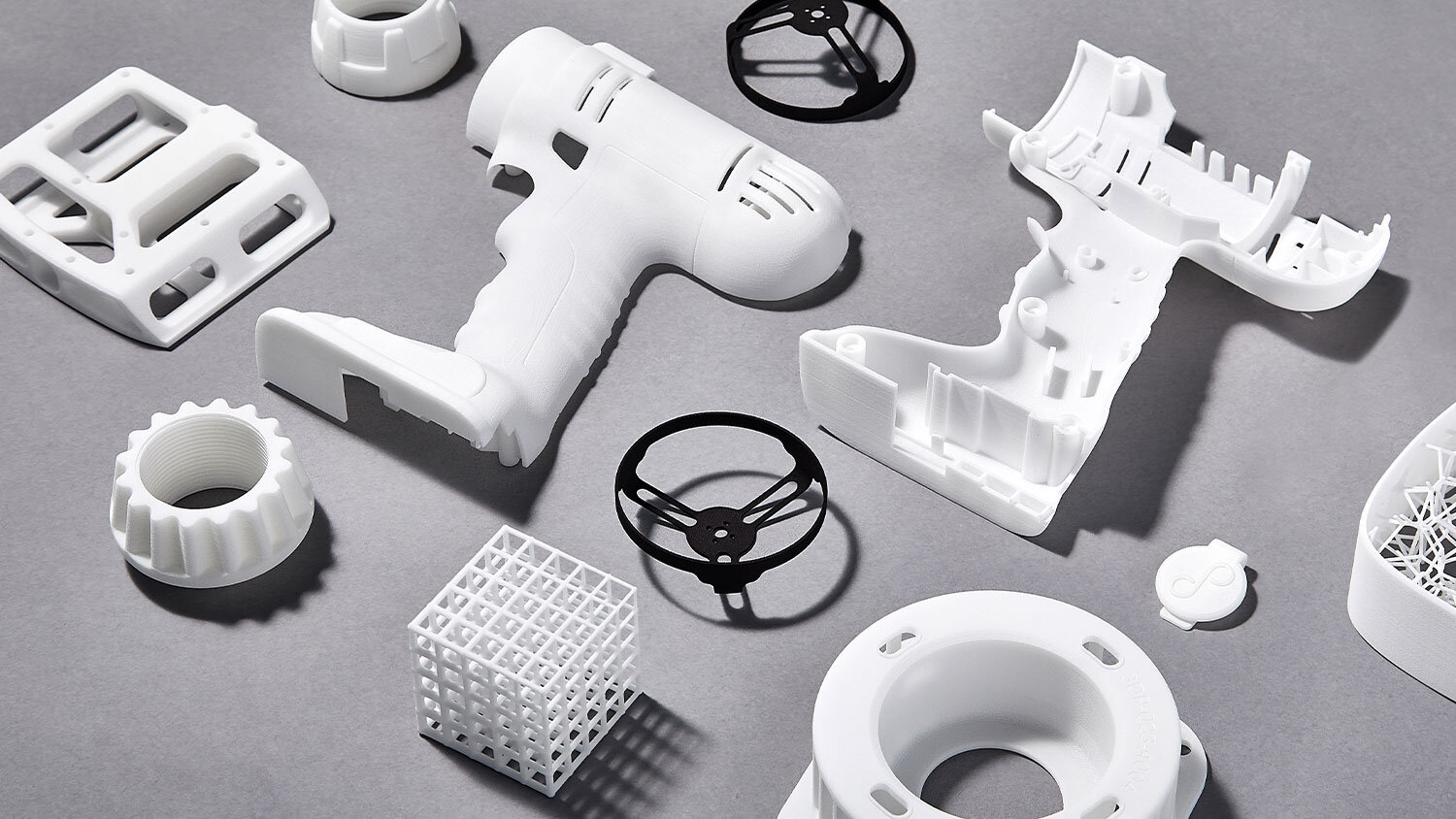

Our FDM printer features a large build volume with dual-nozzle capability, allowing us to print large parts or use support materials for complex geometries. We print in a wide range of thermoplastic materials, selecting the right one based on the part's mechanical, thermal, and chemical requirements. FDM is ideal for functional prototypes, fixtures, jigs, enclosures, and concept models.

Our SLA resin printer produces parts with exceptional surface finish and intricate detail that FDM cannot match. Using a selection of tough, accurate resins, we create prototypes that closely mimic the look, feel, and mechanical properties of injection molded production parts. SLA is ideal for parts requiring fine features, smooth surfaces, tight dimensional accuracy, or visual presentation quality.

For FDM, we offer a wide range of thermoplastics to match the mechanical and thermal requirements of each part. For SLA, our resin selection includes tough and accurate formulations designed to mimic the properties of common injection molding materials - delivering great surface finish and intricate detail with the strength needed for functional testing.