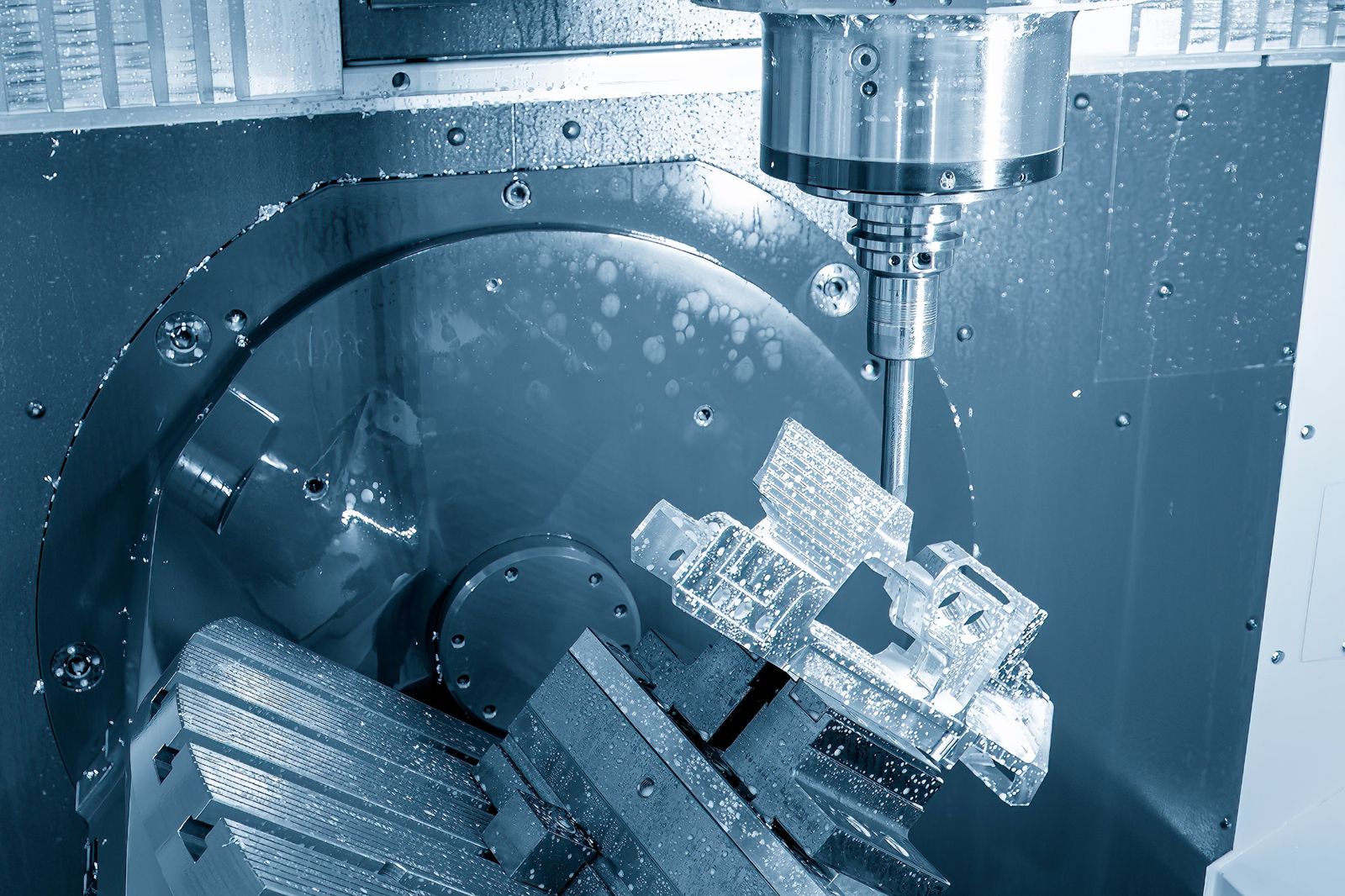

Our primary machining center offers a 500 x 450 x 400 mm (19.7 x 17.7 x 15.7 in) work envelope, an 18,000 RPM spindle with through-spindle coolant, and a 60-pocket automatic tool changer. It handles complex 3D contours, undercuts, and multi-face machining in a single setup - delivering the precision and surface quality needed for functional prototype parts.

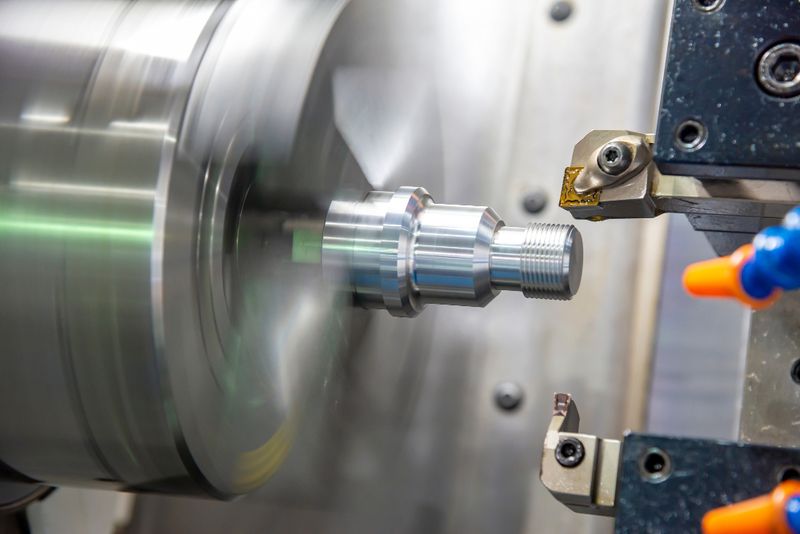

Our 2-axis CNC lathe produces precision turned components - shafts, bushings, spacers, threaded parts, pins, and other rotational geometries. Combined with the 5-axis mill, we can produce complete parts that require both milling and turning operations.

We machine virtually any machinable material. Common materials include aluminum, steel, stainless steel, brass, copper, and engineering plastics such as Delrin, nylon, HDPE, acetal, and UHMW. If your product requires a specific material, we can work with it.

We can easily hold 0.005", and 0.001" or tighter when needed. Tighter tolerances are achievable for critical features and fits. We set tolerances during the engineering phase to ensure every part meets its functional requirements without over-specifying and driving up cost.

In-house bead blasting, sand blasting, and painting allow us to finish parts immediately after machining. For anodizing and powder coating, we work with fast-turnaround partners to keep the project moving without delays.

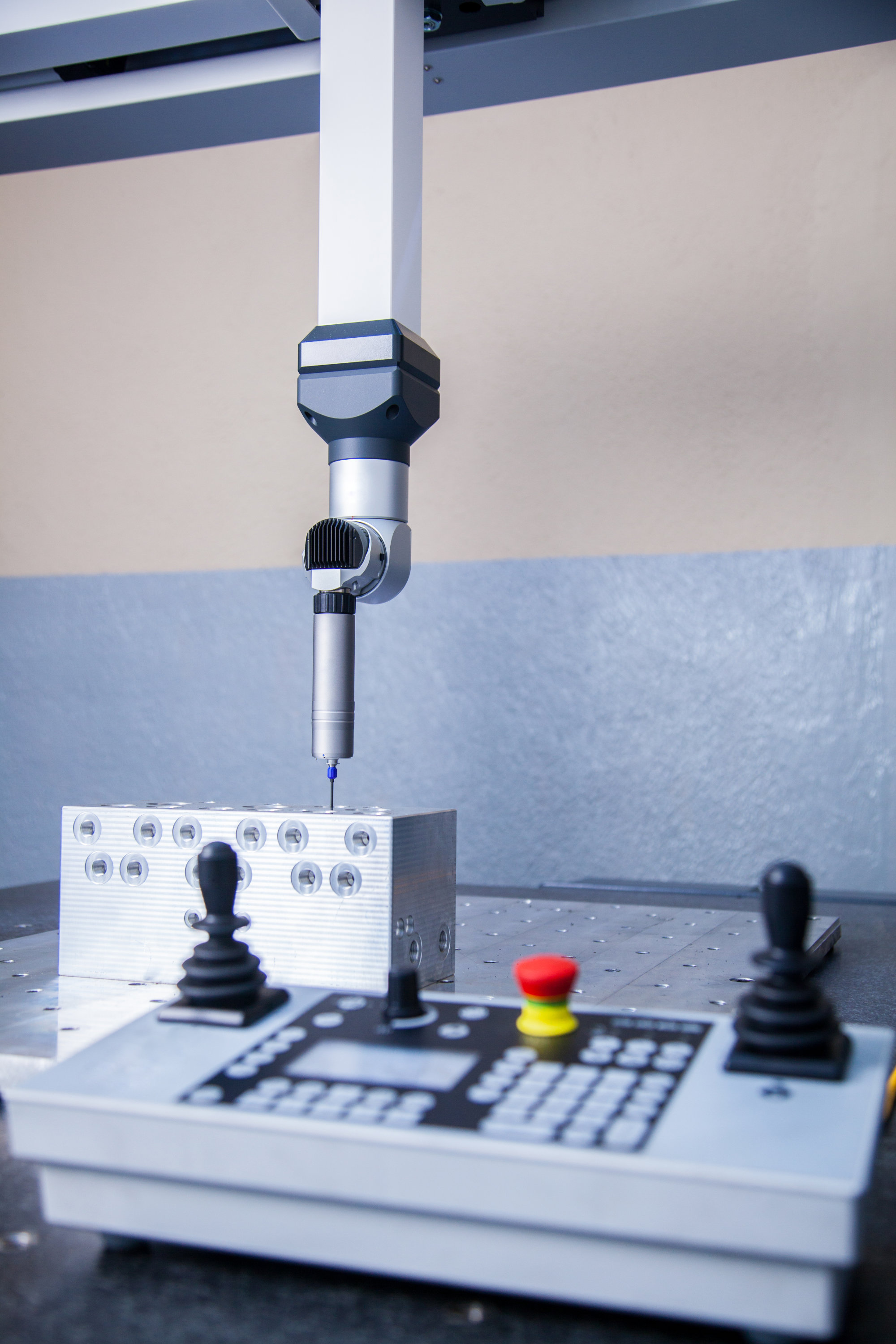

Critical dimensions are verified after machining to ensure parts meet specifications before they move to assembly. This step catches any issues early and confirms that the prototype accurately represents the design.